技术支持

Xilinx support accelerates customer productivity and time-to-market from system development to product end-of-life.

Xilinx support accelerates customer productivity and time-to-market from system development to product end-of-life.

Xilinx has a long legacy of delivering products and services that accelerate the customer design process. Customers have access to an infrastructure that is continuously tuned-to-target defect-free product experiences. While this initiative takes a tremendous level of focus and partnership, the rewards have been extraordinary.

Xilinx has proven repeatedly that structured customer collaborations with high-volume customer applications can achieve levels close to, or at, zero PPM. This disciplined approach creates synergy between Xilinx and customers through joint-design reviews, design evaluation samples, and focused teamwork. These collaborative efforts often extend to provide contract manufacturers with customer engineering support. By working with Xilinx, designers can enjoy superior results through:

- Defect avoidance through collaborative knowledge sharing (training and tutorials) and design reviews

- Better customer experiences with debug tools (including access to design evaluation samples)

- Improved customer design methodologies through the introduction of Vivado™ design-rule-checks (DRCs) and a new handbook focused on design methodologies

- Fewer RMAs through improved development tool quality

- Disseminating key design methodologies based on common lessons learned from more than 20,000 customer interactions across the Xilinx customer base.

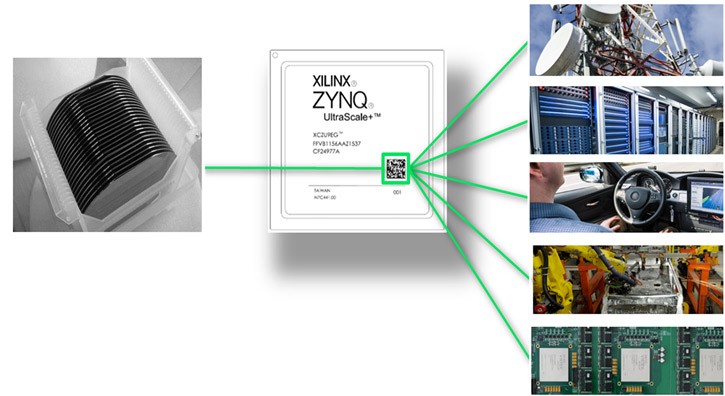

2D Barcode Traceability

Every Xilinx device has a unique 2D barcode linked to its DNA which contains historical data for traceability from wafer to POS (Point-of-Sale).

This 2D barcode enables advanced data analytics through AI / Machine Learning to:

- Enhance operations agility

- Improve quality

- Increase yield

- Faster on-time product delivery

- Increase customer productivity

The 2D barcode can be read using Xilinx Go App which can be downloaded: https://www.xilinx.com//m.alegre-web.com/about/app-download.html.

Additional information about 2D barcode can be found at AR# 67513.

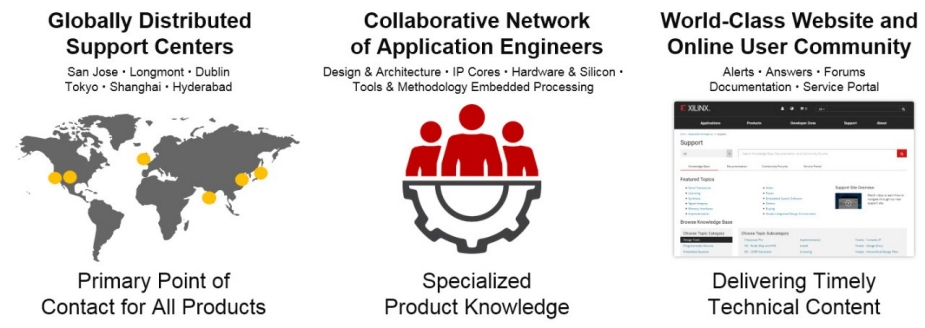

Worldwide Customer Support

Xilinx sales offices, representatives and authorized distributors around the world are available to support customers.

- Technical information is available online 24 hours a day from the Support website

- Technical Support staff are available to respond to your questions in the Community Forums

- Individual assistance from Xilinx Technical Support may be available through Service Portal

Xilinx support page has an extensive knowledge database to answer customer questions.

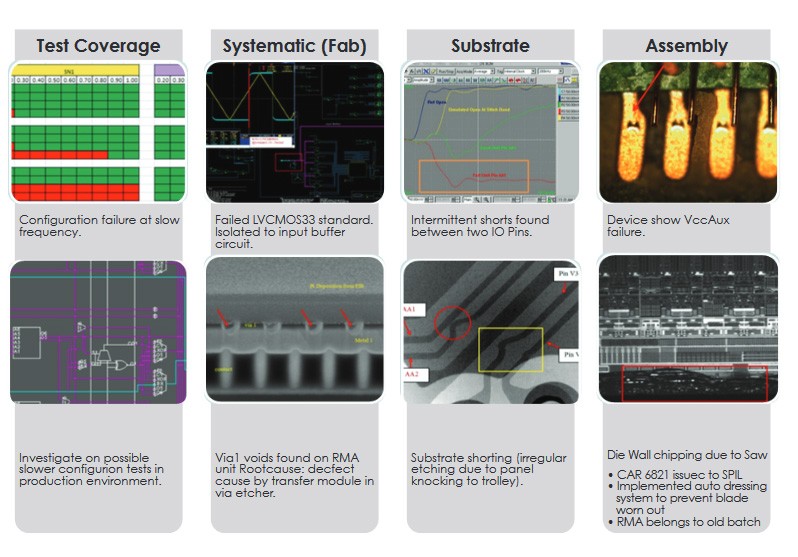

Failure Analysis (FA) Capability

Xilinx and customers—with support from technology suppliers and partners—make-up a tightly linked community. The entire ecosystem must succeed to drive-up the quality of the end-solutions enabled by Xilinx innovations. Periodic quality scorecards provided by customers are therefore the true measure of Xilinx quality.

Fault-isolation and failure-analysis enable our engineering to determine the cause of an issue by scripts, patterns, tools, simulations and other diagnostic methodologies. These electrical-fault diagnostic methods can pinpoint the exact cause and location of the failing circuit. Our failure analysis labs process, collect and analyze data to determine the cause of the failure. Physical inspection of the fault-isolated location in the silicon are mostly the stages during failure analysis. It is a subsequent examination of the cause or cause-of-failure using a wide array of methods, especially microscopy and spectroscopy. Additional Xilinx customer-facing quality hallmarks include:

- Closed-loop focus on root cause

- On-line RMA real-time and on-line customer support tool

- Full 8D root-cause analysis and corrective action leading to continuous improvements

- Executive commitment to improving customer satisfaction

Xilinx customer RMA cases is on the decline over the past 10 years, as show in Continuous Improvement. Our zero-defect strategy and exceeding industry reliability benchmark is working and we expect to improve even further with continuous improvement.

In case any defect is found, Xilinx will relentless drive to discover root-causes of failures. Xilinx has advanced tools capable of analyzing the latest technology nodes beyond 16nm, where even a few micro-amps of current leakage can be detected.

Change Management

Xilinx qualifies products and processes prior to production release. Changes in design, manufacturing, testing, or obsolescence of Xilinx products is communicated following established industry standards.

Xilinx uses JEDEC (JESD46 / PCN and JESD48 / PDN) standards, as the foundation for our customer notification processes related to change or obsolescence. This is supported by a change management infrastructure extended into Xilinx supply chain.

Xilinx communicates through XCN Notifications (Product Change Notice / PCN and Product Discontinuation Notice / PDN) which are posted on Xilinx.com.

- Customers will be notified a minimum of 90 days* before the proposed ship date of the production identified in the PCN. Lack of acknowledgement of the PCN within 30 days constitutes acceptance of the change.

- Customers will be allowed a minimum of 12 months* from the PDN notice to place final orders, and 6 months* from the notice for final shipments.

Customer needing notification for changes and obsolescence are required to register on Xilinx.com. Register today and personalize your “Alerts” area to include Customer Notifications.

*Commercially reasonable efforts will be made but exceptions may apply

Product Longevity

A product lifecycle is typically defined by four main phases: introduction, growth, maturity, and decline.

Xilinx designs products and creates the supporting supply chain with the clear intent to support a minimum 15+ year lifecycle*, starting from first production release. Xilinx parts are used extensively in numerous applications that require a long operational lifetime, and therefore, Xilinx makes a strong commitment to product longevity. With this commitment, although the minimum lifecycle is 15 years, customers will see that the majority of families will be supported much longer. The longevity of Xilinx products is longer than ASSPs, ASICs, and other major FPGA suppliers.

In the case of a last time buy, Xilinx does follow the JEDEC standard

*Does not apply to boards or products with in-package high bandwidth memory DRAM